In 2002, the company’s specialists have developed removable insulation products, as well as have registered trademark TERMOPAKтм.

Products are differented by models, types and performances as: the «hard» and «soft» TERMOPAK products.

Products are manufactured in strict accordance with TU U 26.1-33762208-001:2010 ‘Quick-removable reused insulation TERMOPAK‘

What standards are used for production removable insulation TERMOPAKтм?

According to the SNiP 2.04.14-88 «Thermal insulation of equipment and pipelines» p.2.9.:

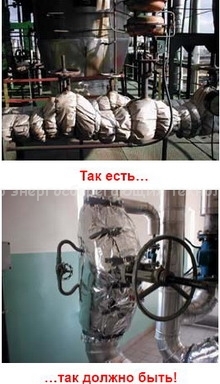

«Removable insulating structures should be used for insulation hatches, flanges joints, fittings, gaskets and expansion bellows of pipes, as well as in places of measurement and check the conditions of insulated surfaces».

Sphere of application of removable insulation TERMOPAKтм:

- pipeline fittings;

- linear sections of pipelines and their elements — branches, reducers, etc.;

- turbines;

- compressors;

- heat exchangers — plate and shell-tube types;

- vessels, including spherical type;

- hatches, flange joints;

- Gaskets and expansion bellows of pipes;

- Any other objects of thermal insulation on the basis of Customers’ specifications.

During the operation of non-isolated fittings the heat losses are equal to the heat losses on straight linear section of pipeline with the same diameter, see examples according to Table:

|

Technical characteristics

|

Index |

|

Density, kg/m3

|

80-100 |

| Operating temperature, оС | up to + 700 |

| Coefficient of thermal conductivity with temperature (25 ± 5)оС, W/(м·К), not more | 0,034 |

| Thermal-insulating materials | Basalt mats Ragos, fiberglass, foam rubber, etc. thermal-insulating materials |

| Covering fabrics | Folmo-, glass-, basalt fabrics, etc.materials |

| H — thickness , mm | 20-200 and more |

Compression, % max |

5-20

|

| Flammability index | Group G1 |

| Packing material | Polyethylene film |

Products TERMOPAKтм are developed and applied to the heat transfer agent’s temperature from -400С to 1500С, to+2500С, to+4000С, to+7000С.

Performance features of products TERMOPAKтм:

- Easy installation — mounting and dismounting of the product may carry out by one person, on pipeline fittings up to diameter Dn200;

- Ease of maintenance — assembly and disassembly of the product may carry out by repair team specialists which is serving the steamshop, boiler room, «hot» workshop;

- Long-term use — the product life of 10-15 years (when removing the product does not lose its functions, it can be re-set on the object during the lifetime — at least 20 cycles of assembly/disassembly); ;

- Fast payback — payback period of the product is approximately from 2 weeks.

TERMOPAKтм in hard housing Product DTV-250/50/100-SK/e-LU-SI.

|

|

|

TERMOPAKтм UNIVERSAL Product DTV-UNI-100/150/50-SI:

|

| TERMOPAKтм FRAMEWORK Product DTV-219/150/50/1000-К/с-LU:

|

|

|

TERMOPAKтм STANDARD Product DTV-250/100-S/d-ТО:

|

TERMOPAKтм WIREFRAME Product DTV-300/700/150-К/с-ТА:

|

|

TERMOPAKтм products are installed both indoors and on air open sites. Term of production — from 2 weeks depending on the size and specifics of the order.

TERMOPAKтм products will provide reducing the operating and service costs of the pipelines fittings, as well as significant savings of the enterprise assets for these operations, as its are very durable and reusable equipment.

OBJECTS OF THERMAL INSULATION:

Chemical, petrochemical and metallurgical production complexes, technological production, food processing and sugar industries, nuclear power, turnover water cycles, steamshops, boilers, power plants, heating systems.

изоляция теплоизоляция изоляционные работы теплоизоляционные работы быстросъемная теплоизоляция быстросъемная тепловая изоляция быстросъемная изоляция съемная изоляция съемная теплоизоляция съемная тепловая изоляция съемные теплоизоляционные конструкции быстросъемные теплоизоляционные конструкции съемные кожуха теплоизоляция тепловая изоляция изоляция теплоизоляция трубопроводов тепловая изоляция трубопроводов тепловая изоляция трубопроводов и оборудования изоляция трубопроводов изоляция труб изоляция для труб изоляция трубная изоляция трубопровода изоляция паропроводов изоляционные материалы теплоизоляционные материалы изоляционные работы изоляция арматуры изоляция трубопроводной арматуры изоляция теплообменников изоляция емкостей изоляция компрессоров изоляция турбин изоляционные работы теплоизоляционные работы теплоизоляция теплоизоляция труб теплоизоляция труб теплоизоляция трубопроводов теплоизоляция паропроводов техническая изоляция техническая теплоизоляция техническая теплоизоляция для трубопроводов