In 2008, our company started production of the completely new product TERMOPAKтм for thermal insulation of pipelines.

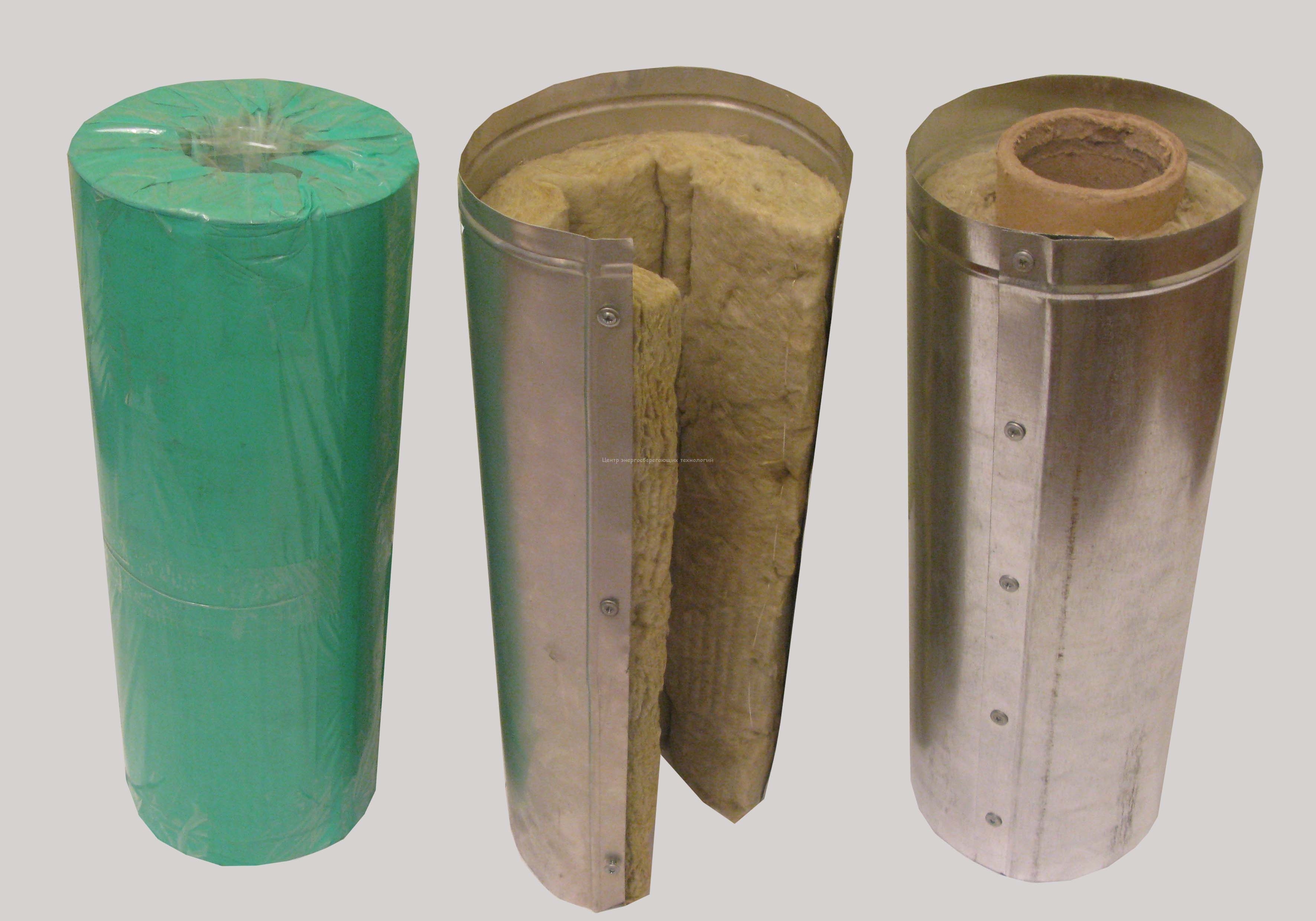

This is removable insulation TERMOPAKтм in zinc galvanized , aluminum and stainless housings.

Why do you need it, so if the installer can mount an insulation in the traditional way?

The answer lies in the human factor. It’s not a secret that during installation some clearances and leakages in the insulation are allowed, and which the simple housing hides. But if in a week of object work the Customer dissatisfied with the quality of steam, the temperature at the surface of the insulation, etc., just a time to take the thermal camera and using it to see the glaring fact — the joints, both longitudinal and transverse are «burning» at the news re-assembled insulation. This indicates that the so-called ‘heat fistulas’ are presented, and through which nonnormable heat losses can reached up to 30% or more.

What is the solution of problem?

Solving the problem is obvious — the installer does not have to leave the choice — to give to him a finished product, assembled in the factory with the required seal joints. The installer having received such a product is forced to remove the screws to dismantle the longitudinal joint. After installation insulation at the pipeline, it is easier for the installer to assamble the product used allready existed holes, not drill new holes for screws. Otherwise the entire assembly had not come out, because products have the same geometry assembly joints.

Thus, the influence of human factors is reduced to minimum and the Customer receives a high quality thermal insulation of his object.

These TERMOPAKтм products are required much less time and finance resources (up to 70%) for installation of insulation compared with traditional technology. Technology of production of these products is unique and provides gluing of the piercing basalt mat to housing. This technology allows the producer to make removable insulated housing with the highest quality.

These new ТЕРМОПАКтм products, also as manufactured previously, are removable reusable products.

Features of TERMOPAKтм removable housings:

1. Product of full factory readiness for insulation works on the steam, hot water pipelines, process pipelines with operating temperature from -400С to +7500С.

2. Used meterials:

2.1. Basalt fiber mats produced by PAROC (Poland).

2.2. Glass fiber, including silica.

2.3. Foamed polyethylene and rubber used for refrigerant insulation.

2.4. Heat-resistant glue.

2.5. Glass yarns and silica threads.

2.6. Zinc galvanized sheet, aluminum sheet and stainless steel sheet.

2.7. Galvanized and anodized self-tapping screws.

3. Density of insulation – 60-100 kg/м3.

4. Insulation thickness — 20-200 mm or more on the basis of calculating the needed thickness of insulation for a particular object.

5. Length of products — 1000 mm.

6. Products are serial, full factory readiness.

7. Products are made to any pipe diameter at the request of the Customer.

8. The company also produces TERMOPAKтм removable housings for installation at all pipeline elements — branches, reducers, T-branches, caps, etc.